On-board kitchens and galley systems for rail cars: maximum function even in the most confined space.

Every day, our on-board kitchens, counter systems, and rail alleys stand the test of international long-distance rail traffic. We manufacture long-lasting, tailor-made solutions that do not only meet the high industrial quality standards but also resist enormous forces reliably.

Since 1960 we have been among the European market leaders in the manufacturing and equipment of counter and canteen systems of the railway industry thanks to our unique know-how in mobile kitchen technology, countless processing options, and our close collaboration with customers. Our on-board kitchens are to be found on almost all rails of the world:

- AT: Mariazellerbahn

- CA: Rocky Mountaineer

- CH: EC 250, LD double-decker, IC 2000, SBB8

- DE: ICE 1, 2, 3, ET 5, ET 7

- ES: AVE

- IT: ETR 500, ETR 1000

- PL: Dart, Restaurant Refit, Flirt PKP

- SE: MTR

- UK: Arriva, FGW Buffet, Virgin Voyager, GNER

Engineering & conceptual designn

By request, we bring in our ideas and experience to your conceptual design and support your planners in optimizing fastening points, cable guides, connections, and air outlets.

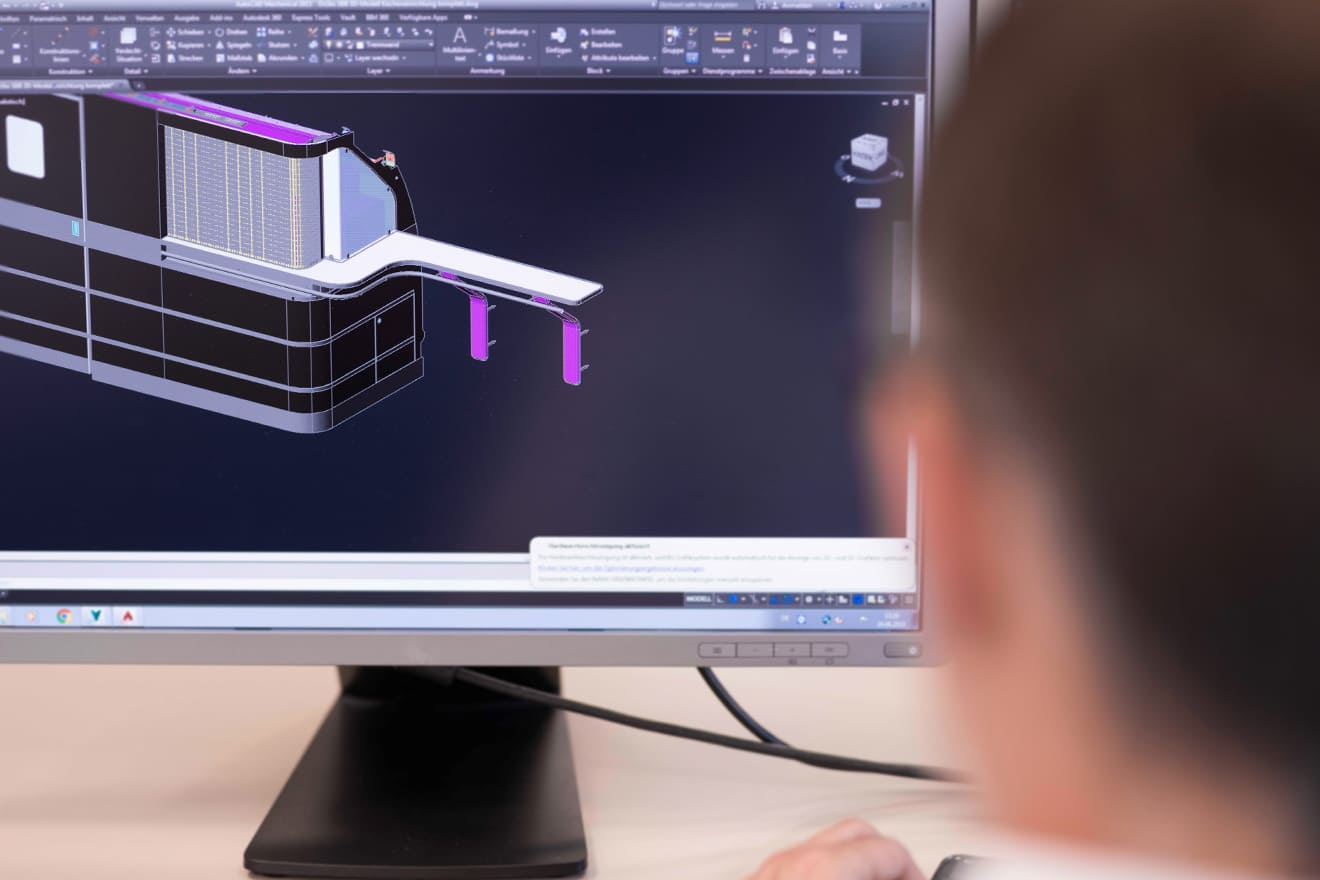

Visualization

According to the design and ground plan drawings our CAD experts visualize your on-board equipment in 3D. As a second step, they further optimize the drawings and convert them into validated design data.

Interface coordination

Many functions require simultaneous or downstream collaboration and a perfect timing of the individual trades. Our project managers coordinate completion of each project phase for smooth collaboration and delivery as scheduled.

Manufacturing

Our special design department manufactures all kinds of equipment and furniture components according to your designers‘ specifications. There are particularly stringent quality requirements on materials and processing steps. Materials used are documented and verified. Railway standards and country-specific provisions are fully met.

Assembly

Our expert teams of mechanics, welders, and fitters do any kind of just-in-time assembly, installation, and connection works. We assemble prototypes in our company to avoid undesirable sources of error already in advance.

Commissioning

Once all the test runs and function tests are done, we do the final acceptance and on-time commissioning of your on-board kitchen and instruct your personnel. Here too we act according to our quality principle: safety first.